Jintai designs and manufactures high-performance sintered metal filters and filter material products for all industries, such as sintered metal fiber felt, multi-layer sintered wire mesh, stainless steel sintered filter, porous metal filter cartridge and specific material filter like sintered nickel filter.

Jintai products have been widely used by many leading industrial companies in petrochemical industry, fine chemical industry, water treatment, pulp and paper making, automobile industry, food&beverage, metal processing and other industries. The independence, experience and expertise of Jintai allow us to provide you with objective advice and customized sintering solutions.

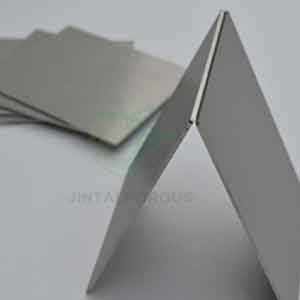

Compared with the ordinary metal woven mesh, Jintai sintered filter has excellent strength, long service life and good corrosion resistance. Also, we can provide custom sizes, materials, and layered configurations to meet your specific specifications.

Sintered Porous Metal Filter Solutions and OEM Services in China

Discover cutting-edge designs and OEM services for sintered metal filter discs with JINTAI. Contact us to explore tailored solutions and find superior metal powder filtration.

Fast OEM Solutions from Leading Sintered Porous Metal Filter Manufacturer

JINTAI offers rapid OEM solutions with a diverse range of materials, layers, sizes, and shapes for sintered porous metal filters, including 316L stainless steel, bronze, and nickel. From single to multiple layers, our filters are crafted from sintered wire mesh, perforated metal, and metal powder. Our extensive inventory includes standard materials for sintered metal filters, enabling us to swiftly produce samples and deliver quick solutions for your projects, expediting production and delivery times.

JINTAI designs and manufactures high-performance sintered porous metal filters and filter material products for various industries. Kindly explore the following products, and for custom requirements, please feel free to contact us directly!

Applications of Sintered Metal Filters

Sintered Metal Filter Working Principle

Jintai designs and manufactures high performance sintered porous metal filter and filtration material products for all industries, such as sintered metal fiber mats, multi-layer sintered wire mesh, stainless steel sintered cartridges, porous metal filters and sintered nickel filters in specific materials.

Jintai sintered porous metal filter have been widely used by many leading industrial companies in petrochemical, fine chemical, water treatment, pulp and paper, automotive industry, food and beverage, metal processing, etc. Jintai's independence, experience and expertise allow us to provide you with objective advice and customized sintered solutions.

Jintai sintered filters offer superior strength, long life and good corrosion resistance compared to ordinary woven metal mesh. Also, we can provide custom sizes, materials and layering configurations to meet your exact specifications.

Please send us your media type, flow rate, filtration accuracy, material requirements, or even other brands of ideal sintered metal cartridges, such as Mott cartridges, GKN sintered metal cartridges, and Norman sintered metal cartridges, and we will quote you immediately.

Unique OEM designs in size, aperture, material, layers, and shape

Professional R&D team providing fast and efficient supply solutions

Products compliant with CE standards, ensuring stable quality

Comprehensive services from engineering to after-sales support

Rich experience and expertise in applications across the chemical, food, and beverage industries.

At JINTAI, we have a proven track record of providing customized and effective solutions to address complex filtration and flow control challenges. Collaborate with us to receive optimal metal filtration solutions tailored to your industry needs. Our dedicated R&D team is committed to delivering the best solutions for your project.

Jintai can produce sintered porous metal filter elements of various materials and sizes, and can also be customized according to customer requirements. We select high-quality metal powder as raw materials and cooperate with strict technology to provide customers with high-quality products. The sintered porous metal filter element of Jintai Company can also be made of various alloys with excellent properties, and its high temperature resistance, corrosion resistance and other properties can serve more working conditions.

The porous metal cups of Jintai Company can be customized in various specifications according to customer requirements, and the parameters such as length, diameter, thickness, material and grade can be changed to meet customer's process requirements. In addition, the porous metal cup can be attached to other metal or non-metal parts.

The double-layer filter element is the patent product of Jintai Company. By controlling different raw materials and adopting a one-time molding process, the gradient distribution of the pore size can be achieved. The double-layer structure plays a role of support and filtration at the same time, and the gradient-distributed pore structure can achieve a good separation effect with lower energy consumption. Compared with the rolled filter element, the double-layer filter element has a more complete structure, does not require welding, and is more corrosion resistant. It is the first choice to replace the rolled filter element and is also a new solution in the field of cross-flow filtration.

The membrane filtration product of Jintai Company is a kind of surface filtration. The surface of this product has a very thin precision filter layer, and the inside is a high-strength support layer. The two layers are sintered at high temperature to form a chemical bond, so the filter layer will not fall off even under harsh working conditions. The Jintai membrane filtration product has low pressure loss during filtration and has a good anti-cleaning effect, which can greatly extend the service life of the filter element.

The porous metal discs of Jintai Company can be customized in various specifications according to customer requirements, and the parameters such as diameter, thickness, material and grade can be changed to meet customer process requirements. In addition, the discs can be encapsulated in various metal or non-metal parts for use.

The porous metal square plate of Jintai Company can be customized in various specifications according to customer requirements, and the parameters such as length, width, thickness, material and precision can be changed to meet customer's process requirements.

The porous metal tubes of Jintai Company can be customized in various specifications according to customer requirements, and the parameters such as length, diameter, thickness, material and precision can be changed to meet customer's process requirements. In addition, the porous metal tube can be connected to other metal parts to form a whole.

Jintai can customize sintered porous metal filter for any industry, with various parameters, specifications, shapes and pictures, and we can provide you with an accurate quote and reasonable delivery date!

Compared to other types of filtration materials such as stainless steel wire mesh, ceramic, glass fiber, and filter paper, Jintai sintered porous metal filter have higher mechanical strength and compressive strength. Jintai cartridges provide you with excellent filtration performance in both very high and very low temperature environments.

Easy to form, machine, weld and clean

Filtration accuracy of 0.2 to 1000 microns

High-intensity cleaning and multiple use

Customized service for various materials and sizes

Commonly used in -200℃ to 650℃ and acid and alkali corrosive environment

Porosity is capable of retaining solid particles contained in liquid or gaseous fluids and partially separating liquid and solid phases or gaseous phases of different molecular weights. This property can be used to filter a variety of fluids with different characteristics.

Porosity reduces the pressure of the fluid passing through it, a phenomenon known as pressure loss. This phenomenon is used to suppress the sound of pressurized gases (silencers) or to protect hydraulic equipment and electronic devices.

Porosity allows the fluid to pass through it with a constant flow rate at the outlet of the porous member, especially when the flow is generated by capillaries. In this way, a precise control of the output flow of the fluid stored under pressure is achieved.

The passage of pressurized gas through porosity results in a constant, controlled gas flow rate at the outlet of the porous component, with the same pressure distribution at all points. In this way, liquids can be vaporized or aerated, providing a constant gas flow rate, or powdered solids can be manipulated by fluidization.

Porosity is capable of retaining and condensing moisture in the gas passing through it. This property is used to dry and protect equipment from corrosion.

The presence of porous components in front of the flame prevents the flame from receding. Common applications are gas boilers, heaters, welding facilities, etc.

Any pressure driven filtration process with high operating costs in applications with constant high temperatures and corrosive environments can be improved by Sintered Porous Metal Filte technology.

Petrochemical industry, water purification, nuclear facilities, heat exchangers, ozone, transportation of chemical powders, recovery of catalysts, general drying, general, manufacturing of chemical products, pharmaceutical industry, hydrogen purification, etc.

Gasification of liquids and liquids, evaporators, fluidization and transport of powdered solids, packaging manufacturing, dairy industry, bacterial ultrafiltration, etc.

Pneumatic and hydraulic circuits (compensators, traps, regulators, silencers), protection of sensors and instruments, gear motors, cylinders, welding, industrial gases, industrial filtration, fire extinguishers, molds, sprayers, boilers, etc.

Automobile, ship, aviation, railroad, etc.

Boilers, heaters, gas burners, printers, etc.

Aquariums, underwater fishing, clinical analysis, medicinal gases, protection of electronic devices, energy, personal care, measuring equipment, various machines, etc.

When selecting a sintered metal filter, consider the required particle retention, the flow rate through the filter, the operating fluid, and more. Our last blog post on filter design considerations focused on specific applications, such as fuel filters and hydraulic oil filters in industries such as aerospace, defense and marine. When considering sintered metal filters more specifically, you'll want to know the following additional points.

Pore Size - Also known as micron rating, pore size defines the size of particles you want to block. If a filter is rated at 5 microns "absolute", this means that 99% of particles larger than 5 microns in size will be blocked. If you specify a "nominal" rating of 5 microns, you are allowing a much larger percentage of 5 micron particles to pass, perhaps as much as 60%.

Pressure Drop - This is the pressure loss that occurs as the liquid or gas flows through the filter. You must determine how much pressure your specific application will allow and specify this to the filter manufacturer.

Temperature Range - How hot or cold your filter will operate. The metal alloy you choose for your filter must be able to tolerate it.

Strength - Sintered filters are a good choice when high strength is required. Another advantage is that they provide the same level of strength in forward or reverse flow.

Please see the previous section on design considerations. Before ordering a sintered metal filter, you need to thoroughly understand your application. The following questions need to be answered prior to fabricating a mold for a sintered filter.

What will pass through the filter?

What is the corrosion problem?

What special operating conditions, such as temperature or pressure, are involved?

What contaminants may be encountered?

What sizes, shapes and tolerances are required?

How many units will be required?

How will the filter be mounted or supported?

What is the ideal flow rate and allowable pressure drop across the filter unit?

What is the overall pressure of the system?

With the answers to the above questions our professional engineers will be able to answer any questions you may have! (Estimates?, technical?, advice?, etc.)

Jintai company has been committed to the development of metal porous materials and related technologies and applications. As early as more than 20 years ago, Jintai began to focus on the development and production of metal porous powder sintered filter elements. It has 15 invention patents and utility model patents. It has been a high-tech enterprise and has passed ISO9001 quality management system certification. After more than 20 years of technical accumulation, Jintai can now provide customers with a variety of product materials and specifications to meet customer needs.